Knowledge

2021-05-11 9805

Cast iron- JCG Industrial Co., Ltd. Manufacturing Factory

Carbon-iron balance diagram

.jpg)

cast iron

A. Ferroalloys with a carbon content higher than 2.1wt%C, the carbon in common cast iron is about 3.0 to 4.5wt%C, and other alloys are added to see the carbon-iron balance diagram. Cast iron is liquid at 1150~1300℃, low Because of the melting temperature of steel, cast iron is easy to melt and cast. Casting is the most convenient manufacturing method. Xueming Iron Carbon (Fe3C) is a steady-state compound that will decompose into α-fertilizer iron and graphite under appropriate conditions.

Fe3C -> 3Fe(α)+(graphite)

B. Type of cast iron:

Gray cast iron, ductile cast iron, shrinkage graphite cast iron, white cast iron (it becomes malleable cast iron after graphitization annealing),

Low alloy cast iron, anti-wear cast iron, high temperature resistant cast iron, corrosion resistant cast iron.

1.Gray cast iron

The content of carbon and silicon in cast iron is between 2.5 to 4.0 wt%, and 1.0 to 3.0 wt%, respectively. Generally speaking, the graphite in gray cast iron is in the form of flakes, and the surrounding is α fertilizer grain iron or polished iron substrate. These flake graphites have a gray cracked section, which is called gray cast iron. It has good fluidity during casting and small shrinkage. It can cast complex shaped castings.

.jpg)

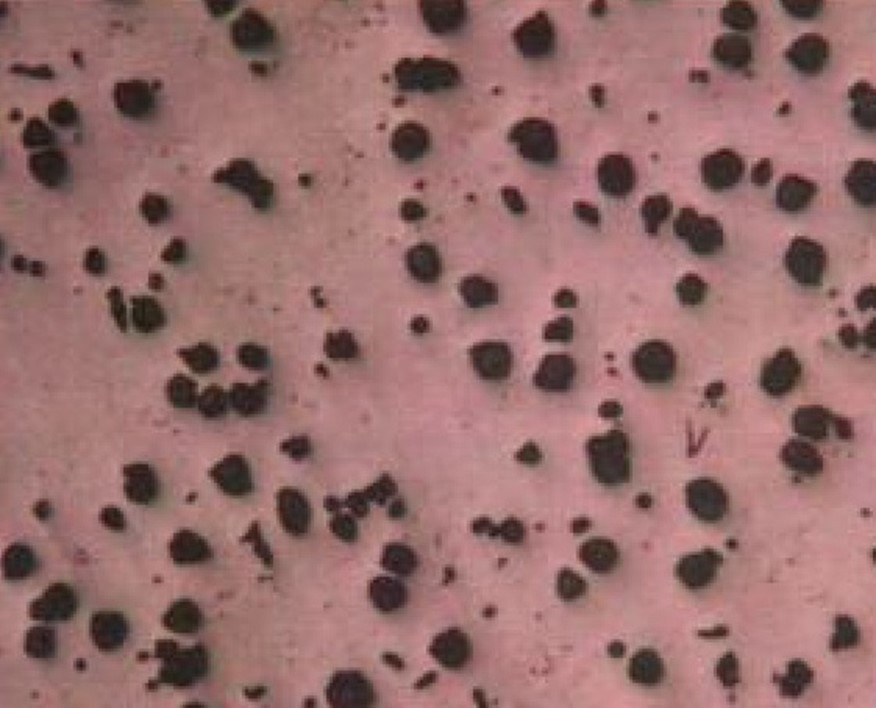

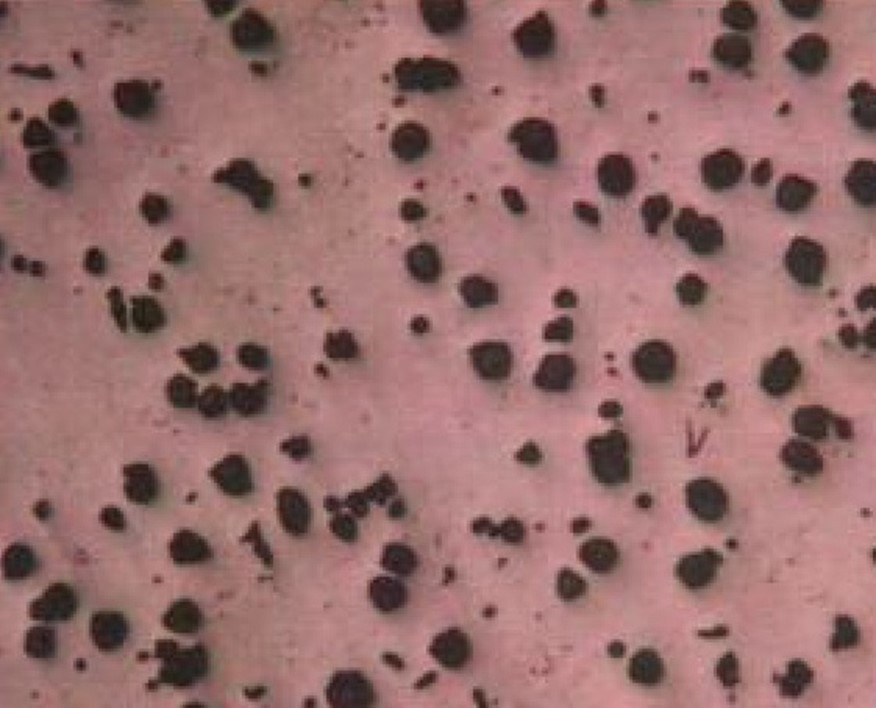

2. Ductile ductile cast iron

Adding magnesium or cerium to gray cast iron before casting, or both at the same time, can produce different structures and mechanical properties. Graphite is spherical, not flake, so this cast iron is called ductile or ductile cast iron. The mechanical properties of ductile cast iron are similar to those of steel. For example, the tensile strength of ductile cast iron with a ferrite base is between 380 and 480 MPa (55,000 to 70,000 psi), and the ductility (elongation) is 10 to 20%.

3. White spreadable cast iron

Low-silicon cast iron with a silicon content of less than 1.0 wt%. It cools quickly during solidification. Most of the carbon will be in the form of Xueming carbon iron instead of graphite. This type of cast iron has a white fracture surface and is called white cast iron. . White cast iron is a transitional structure that produces malleable cast iron.

.jpg)

C. Number of gray cast iron, ductile cast iron, malleable cast iron, minimum mechanical properties, approximate composition and application

Grey cast iron

Ductile cast iron

White malleable cast iron

Taiwan No.:

Gray cast iron FC150, FC200, FC250, FC300, FC350

Ductile iron FCD400, FCD450, FCD500, FCD600, FCD700, FCD800

Shrinked stone-ground cast iron FCV350, FCV370

Voss tempered ductile iron FCD900A, FCD1000A, FCD1200A

.jpg)

cast iron

A. Ferroalloys with a carbon content higher than 2.1wt%C, the carbon in common cast iron is about 3.0 to 4.5wt%C, and other alloys are added to see the carbon-iron balance diagram. Cast iron is liquid at 1150~1300℃, low Because of the melting temperature of steel, cast iron is easy to melt and cast. Casting is the most convenient manufacturing method. Xueming Iron Carbon (Fe3C) is a steady-state compound that will decompose into α-fertilizer iron and graphite under appropriate conditions.

Fe3C -> 3Fe(α)+(graphite)

B. Type of cast iron:

Gray cast iron, ductile cast iron, shrinkage graphite cast iron, white cast iron (it becomes malleable cast iron after graphitization annealing),

Low alloy cast iron, anti-wear cast iron, high temperature resistant cast iron, corrosion resistant cast iron.

1.Gray cast iron

The content of carbon and silicon in cast iron is between 2.5 to 4.0 wt%, and 1.0 to 3.0 wt%, respectively. Generally speaking, the graphite in gray cast iron is in the form of flakes, and the surrounding is α fertilizer grain iron or polished iron substrate. These flake graphites have a gray cracked section, which is called gray cast iron. It has good fluidity during casting and small shrinkage. It can cast complex shaped castings.

.jpg)

2. Ductile ductile cast iron

Adding magnesium or cerium to gray cast iron before casting, or both at the same time, can produce different structures and mechanical properties. Graphite is spherical, not flake, so this cast iron is called ductile or ductile cast iron. The mechanical properties of ductile cast iron are similar to those of steel. For example, the tensile strength of ductile cast iron with a ferrite base is between 380 and 480 MPa (55,000 to 70,000 psi), and the ductility (elongation) is 10 to 20%.

3. White spreadable cast iron

Low-silicon cast iron with a silicon content of less than 1.0 wt%. It cools quickly during solidification. Most of the carbon will be in the form of Xueming carbon iron instead of graphite. This type of cast iron has a white fracture surface and is called white cast iron. . White cast iron is a transitional structure that produces malleable cast iron.

.jpg)

C. Number of gray cast iron, ductile cast iron, malleable cast iron, minimum mechanical properties, approximate composition and application

Grey cast iron

| Grade | UNS No. |

Application |

| SAE G1800 | F10004 | Castings without regard to strength |

| SAE G2500 | F10005 | Small cylinder head, cylinder head, piston, clutch plate, transmission housing |

| SAE G4000 | F10008 | Diesel engine castings, gaskets, cylinders and pistons |

Ductile cast iron

| Grade | UNS No. |

Application |

| ASTM A536 60-40-18 |

F32800 | Parts under pressure, Such as valve, pump body |

| 100-70-03 | F34800 | High-strength gears, And mechanical components |

| 120-90-02 | F36200 | Pinions, gears, Roller, slider |

White malleable cast iron

| Grade | UNS No. |

Application |

| 32510 | F22200 | Normal temperature and High temperature general engineering equipment |

| 45006 | 一 | Normal temperature and High temperature general engineering equipment |

Taiwan No.:

Gray cast iron FC150, FC200, FC250, FC300, FC350

Ductile iron FCD400, FCD450, FCD500, FCD600, FCD700, FCD800

Shrinked stone-ground cast iron FCV350, FCV370

Voss tempered ductile iron FCD900A, FCD1000A, FCD1200A