Knowledge

2021-05-17 31698

Steel pipe for machine structure STKM 11A 12A12B12C 13A13B13C 14A14B14C 15A15C 16A16C 17A17C 18A18B18C 19A19C 20A-JCG Industrial Co., Ltd. Manufacturi

Carbon steel pipe for STKM machine structure

S-Steel; T-Tube; K-Construction Kozo (Japanese); M-Machine

Carbon steel pipe for mechanical structure: National Standard CNS 4437 JIS G3445 G3103

STKM11A ~ 18C / DIN ST52 / ASTM A106, the precision and surface roughness of cold drawn precision steel pipes with inner and outer diameters are better than those of hot rolled pipes.

In order to achieve a higher degree of tensile strength, yield strength, elongation and other requirements; cold drawn precision steel pipes for inner and outer diameters can be used for

Pneumatic cylinders; hydraulic cylinders; shock absorbers for motorcycles and bicycles; condensers for air-conditioners; front forks and rear forks of motorcycles;

Robotic arm; film recycling granulator; exhaust pipe; bottle blowing machine; leveling machine; jack; tiller; roller for printing machinery, etc.

Carbon steel pipe STKM for mechanical structure application range:

■ Air cylinder

■ Hydraulic cylinder

■ Construction machinery

■ Agricultural machinery

■ Boiler tube

■ Mechanical engineering:

punch

Plastic injection machine

Blow molding machine

Food Machinery

Stacker

■ Transportation:

Automobile, motorcycle, bicycle shock absorber

Truck lift

Excavator

crane

■ Sports equipment

■ Medical equipment

■ Ship machinery

■ Air pressure bar for office chair

■ Jack

S-Steel; T-Tube; K-Construction Kozo (Japanese); M-Machine

Carbon steel pipe for mechanical structure: National Standard CNS 4437 JIS G3445 G3103

| Material composition | |||||

| Grade | Chemical composition | ||||

| C | Si | Mn | P | S | |

| STKM11A | 0.12 max |

0.35 max |

0.60 max |

0.040 max |

0.040 max |

| STKM12A | 0.20 max |

0.35 max |

0.60 max |

0.040 max |

0.040 max |

| STKM12B | |||||

| STKM12C | |||||

| STKM13A | 0.25 max |

0.35 max |

0.30~ 0.90 |

0.040 max |

0.040 max |

| STKM13B | |||||

| STKM13C | |||||

| STKM14A | 0.30 max |

0.35 max |

0.30~ 1.00 |

0.040 max |

0.040 max |

| STKM14B | |||||

| STKM14C | |||||

| STKM15A | 0.25~ 0.35 |

0.35 max |

0.30~ 1.00 |

0.040 max |

0.040 max |

| STKM15C | |||||

| STKM16A | 0.35~ 0.45 |

0.40 max |

0.40~ 1.00 |

0.040 max |

0.040 max |

| STKM16C | |||||

| STKM17A | 0.45~ 0.55 |

0.40 max |

0.40~ 1.00 |

0.040 max |

0.040 max |

| STKM17C | |||||

| STKM18A | 0.18 max |

0.55 max |

1.50 max |

0.040 max |

0.040 max |

| STKM18B | |||||

| STKM18C | |||||

| STKM19A | 0.25 max |

0.55 max |

1.50 max |

0.040 max |

0.040 max |

| STKM19C | |||||

| STKM20A +Nb 或 V 0.15max |

0.25 max |

0.55 max |

1.60 max |

0.040 max |

0.040 max |

| Mechanical properties | |||||

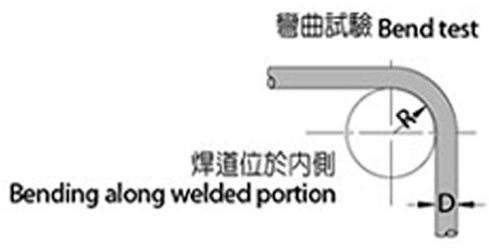

| Grade | Stretching test | Bend | P | ||

| Tensile T.S N/mm |

Yield Y.P. N/mm |

EF |

|||

| STKM11A | 290min | -- | 30 min |

180° | 1/2 D |

| STKM12A | 340min | 175min | 30 min |

90° | 2/3 D |

| STKM12B | 390min | 275min | 20 min |

90° | 2/3 D |

| STKM12C | 470min | 355min | 15 min |

- | - |

| STKM13A | 370min | 215min | 25 min |

90° | 2/3 D |

| STKM13B | 440min | 305min | 15 min |

90° | 3/4 D |

| STKM13C | 510min | 380min | 10 min |

- | - |

| STKM14A | 410min | 245min | 20 min |

90° | 3/4 D |

| STKM14B | 500min | 355min | 10 min |

90° | 7/8 D |

| STKM14C | 550min | 410min | 10 min |

- | - |

| STKM15A | 470min | 275min | 17 min |

90° | 3/4 D |

| STKM15C | 580min | 430min | 7 min |

- | - |

| STKM16A | 510min | 325min | 15 min |

90° | 7/8 D |

| STKM16C | 620min | 460min | 7 min |

- | - |

| STKM17A | 550min | 345min | 15 min |

90° | 7/8 D |

| STKM17C | 650min | 480min | 5 min |

- | - |

| STKM18A | 440min | 275min | 20 min |

90° | 7/8 D |

| STKM18B | 490min | 315min | 18 min |

90° | 7/8 D |

| STKM18C | 510min | 380min | 10 min |

- | - |

| STKM19A | 490min | 315min | 18 min |

90° | 7/8 D |

| STKM19C | 550min | 410min | 10 min |

- | - |

| STKM20A | 540min | 390min | 18 min |

90° | 7/8 D |

.jpg) .jpg) |

|||||

STKM11A ~ 18C / DIN ST52 / ASTM A106, the precision and surface roughness of cold drawn precision steel pipes with inner and outer diameters are better than those of hot rolled pipes.

In order to achieve a higher degree of tensile strength, yield strength, elongation and other requirements; cold drawn precision steel pipes for inner and outer diameters can be used for

Pneumatic cylinders; hydraulic cylinders; shock absorbers for motorcycles and bicycles; condensers for air-conditioners; front forks and rear forks of motorcycles;

Robotic arm; film recycling granulator; exhaust pipe; bottle blowing machine; leveling machine; jack; tiller; roller for printing machinery, etc.

Carbon steel pipe STKM for mechanical structure application range:

■ Air cylinder

■ Hydraulic cylinder

■ Construction machinery

■ Agricultural machinery

■ Boiler tube

■ Mechanical engineering:

punch

Plastic injection machine

Blow molding machine

Food Machinery

Stacker

■ Transportation:

Automobile, motorcycle, bicycle shock absorber

Truck lift

Excavator

crane

■ Sports equipment

■ Medical equipment

■ Ship machinery

■ Air pressure bar for office chair

■ Jack